Well were nearly finished for now.

Here is was earlier in the week.. Going to be a lynx killing machine I hope.

Here are some finished photos of it. Looks better than it did and is more functional for my son who is 6’6”.

Got carried away painting at 1 am. Couldn't stop. I wouldn't make it in an auto body paint shop but Hey the grit and dirt will help the traction on the floor boards. Reminded me of the new paint job you see on the 1930's tractors. They look real nice from a distance. ;0)

First was the seat project.

I made a mistake using 2 by 6. Should have used plywood. Next one. Missing from the photo is a wood strip to keep it snug.

Had some trouble attaching from the bottom. If you drill make sure you align your hold with that of a cleat cog hole in the track so you can see the hole.

Found some thin veneer at the dump. Thought it would keep the material from chafing.

Next step was the handle bar riser. Made from 3 by 2 rectangular Alum tubbing. There was plenty of cable length for it. I believe the handlebars came of a mongoose bicycle. ;0) They are about 2 inches wider than the stock bravo. A little short also. We just bought 5.5 inch bolts and squeezed it together.

Had to grind down the centerpost a bit on the shaft.

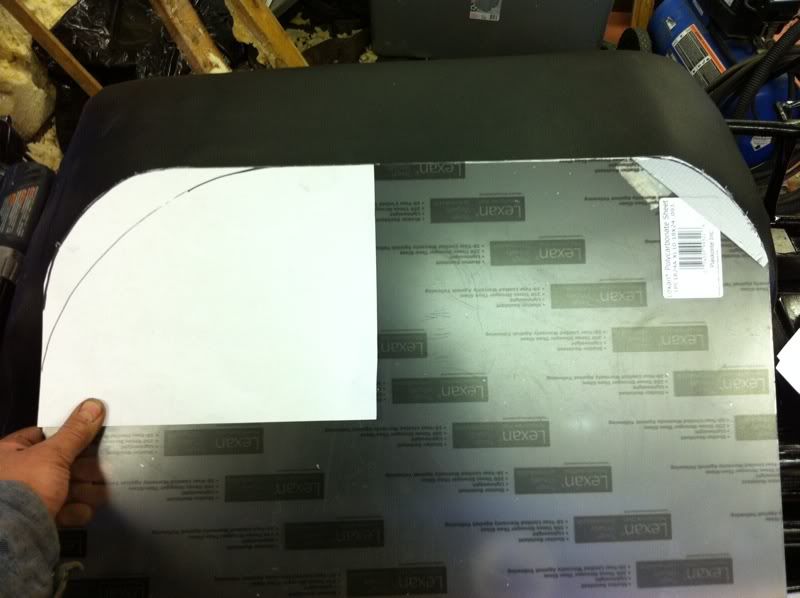

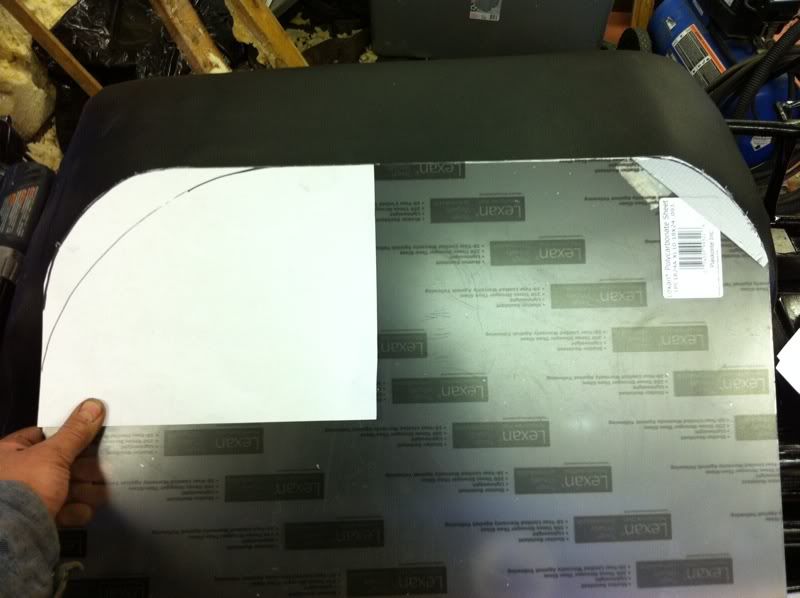

Next it was windshield. With the addition of lexan we needed to have the the existing one as vertical as I could get it. I opted to abandon the previous methods to attach the windshield and came up with my own invention. A little wood and some scrap aluminum and were set.

Cut out the windshield and were nearly ready. I like to clamp the windshield and drive it to hold it until adjusted.

Still dreaming. Should be handy.