Thank s might help too if you really wanna get fancy

So the base trap is an unmodified Sleepy Creek #2DBLS I got in a trade. So first thing we need to do is clean off the jaws and jaw faces, a flap disk on the ole' angle cleans it up real nice in a few swipes.

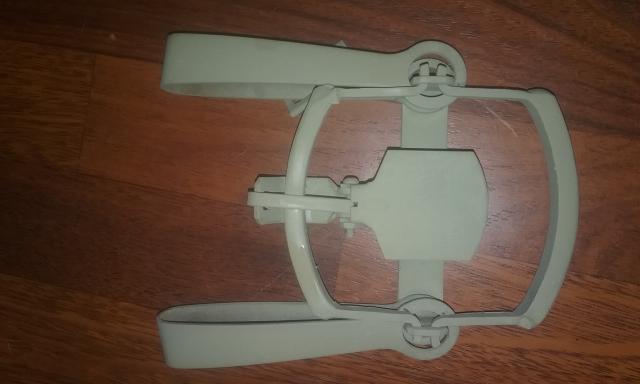

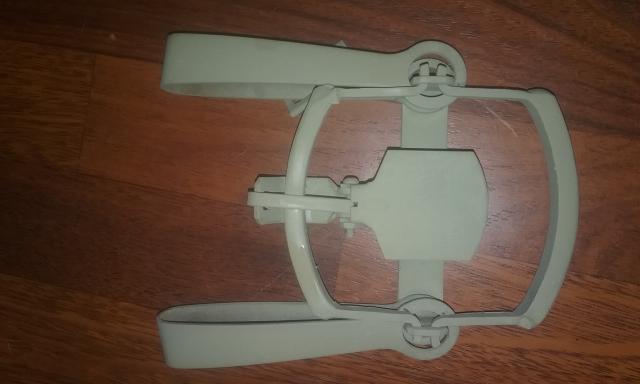

Before

After

Now we laminate the trap. Im using pieces of cattle pannel. If you don't use a material heavy enough you can bun through it while welding the seam shut. One problems with the pannel is its pretty heavy so you wanna bend it a lil so it confirms to your jaws .

Clamped before welding

After

Now we need to either remove or clamo the springs down so theirs no pressure in the jaws . if you don't know what your doing the pressure fromthe springs Can warp the jaws while welding due to heat. If you've never done this CLAMP OR REMOVE SPRINGS ! As you see here I have mine clamped with some vice grips so I can work .

Now were going to welded the seam between the jaw and the lamination. This is also a good time to weld your lugs if you want it off set.

Just wanna show how hot your jaws can get and why you wanna be carful.

Now the seam is welded were gonna grind everything down flush. Again a flap disk is best.

Before

After

Make sure not to grind too long in one spot,you'll and up washing out the jaw..

Lil bit of paint aaand

This isn't needed but I know some films love the way this looks so hope this helps !