I embarked on a similar adventure this year. To build a tumbler. How to do it is a bigger issue than initially thought. These aren't very good pics, but PM me, and I'll take some video if you want a better look kade. These may give you some ideas, and some food for thought.

This is a gear reduced motor turning at 12rpm. With the lower gear on the tumbler shaft, I achieved about 16. I initially had an issue with the mounting bracket and being able to keep tension on the belt, and keeping the belt straight. I personally like Monster Toms motor and drive assembly, and, I believe my stand will accommodate such an adaption later. For the time I have resolved the issue and run at 12rpm.

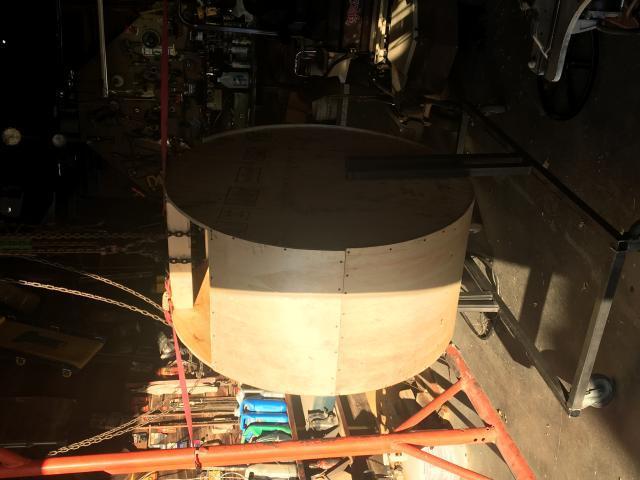

My tumbler drum is 4' tall and 24" on the inside. The height of my stand allows me to stand up inside the drum, from the floor, and vacuum it out. The height of my stand would accommodate a 6' drum. I will say that, you begin adding a lot of weight to the outer portions of the drum with paddles and doors, these effect the balance of the drum itself, and the torque needed to initiate turning. Add into that, a media of sawdust or something similar, with several furs, and weight and torque are major considerations. Monster Toms motor location and drive assembly both take advantage of the weight factor, where the weight of the drum contents would ensure better/full contact with what I'd call a friction-drive (cause I don't know what to call it).

The base of my stand is adjustable, one side slides inside the other square tubing on the bottom, with two bolts welded in on each side to set it.

Couple pics of the solid door and the screen for the drum, before being placed in the stand.

12" plates with 3/4" axel welded on them. Four lag bolts hold them on. The lag bolt heads are covered on the inside of the drum by FRP, a bathroom wall product, fiberglass based. I also used this as the outer covering. I would consider other products for the outer drum shell. The FRP is doing fine for the size drum I have, but a larger drum I'd want a heavier/stiffer material.

Door opening construction. I used a pvc product that resembles wood. Aztec was the brand name. These were scrap pieces from construction jobs. It's a durable, easy to work with product.

My door is much wider than the opening. I wanted to reduce as much dust as possible, because they produce dust if you run dry fur and dry media. More noticeably I should say. The edges of my door actually fit snuggly against the drum wall on both sides. It helps I believe. Plus it eliminated two edges inside the drum that fur could possibly snag on.

Depending on your skill level with tools and projects, I'd look before I leapt. It's not cheap unless you have a lot of stuff just laying around, and the ability to use it. If you're up to the challenge I say go for it. Definitely have some well thought out plans going in. Hope this helps.